Busse tools with multiplex support mold

Short delivery times and low tool costs are essential in a limited market segment. These requirements are also preconditioned by the trend towards ever smaller quantities.

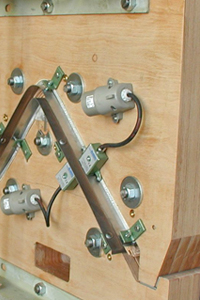

The construction of a press tool made of multiplex or beech plywood slats consists of an unheated support mould which is screwed free of extension to a 10 – 12 mm-thick electric heating plate and insulating interlayer. For forming operations at several levels, shaped intermediate (daylight) heating plates can be produced. When work is carried out with high-frequency generators, electrode sheets made of brass or aluminium are fastened onto the pressing surfaces of the mould.

- Maximum temperature range: 95°C

- Maximum pressure: 25 kg/cm²

Advantages:

- Only the heating plates are heat – not the entire mould mass.

- Short lead times

- Low heat radiation

- Minimum heat loss

- The top and bottom moulds can be heated separately (which makes it possible to pre-stress the mouldings).

- Economical and quick fabrication

If desired, the mold support can also be produced by the customer. In addition to competence and reliability, you can also expect the highest degree of flexibility from us. On request, all tools can also be supplied with the following extra features:

- Logo stamp

- Centring distances

- Supplementary sheets

- Stainless-steel sheets

- Multi-level components to enhance productivity

- Simplified handling of the tools through special cut-outs for lift truck forks

- Narrow radii can be realised through the use of aluminium tips